Al5052 Aluminum Honeycomb Mesh With 15MPa High Strength Used For

AEROSPACE

Product Description of aluminum honeycob mesh:

Aluminum Honeycomb Mesh is a high-strength and lightweight material

composed of aluminum alloy foil cell walls and honeycomb core. It

is widely used in various industries such as rail transit due to

its excellent strength, sound insulation, and lightweight

properties. The cells are available in various sizes from 0.8mm to

45mm, while the foil thickness is usually 0.04mm to 0.18mm,

depending on the type of foil used, such as single layer, double

layer, and multi-layer. The panel thicknesses for Aluminum

Honeycomb mesh range from 1mm to 200mm, depending on the

application. In addition, it provides excellent sound insulation

properties, making it suitable for applications requiring noise

control.

Technical Parameters of aluminum honeycomb mesh:

| Parameter | Value |

|---|

| Width | Customized |

| Material | Aluminum |

| Application | AEROSPACE |

| Color | Silver, Black Etc. |

| Alloy | 5052 |

| Cell Size | 0.8-45mm |

| Shape | Round, Square Etc. |

| Length | Customized |

| Foil Thickness | 0.025-0.2mm |

| Features | Sound insulation |

Applications:

Aluminum honeycomb mesh finds a wide range of applications across

various industries due to its unique properties. Some common

applications include:

Aerospace Industry: Aluminum honeycomb mesh is extensively used in

the aerospace industry for manufacturing aircraft components, such

as cabin walls, flooring panels, interior partitions, galleys, and

overhead stowage compartments. Its lightweight nature helps in

reducing the overall weight of the aircraft, contributing to fuel

efficiency and increased payload capacity.

Automotive Industry: In the automotive industry, aluminum honeycomb

mesh is utilized for lightweight structural components, such as

vehicle body panels, doors, hoods, and trunk lids. Its high

strength-to-weight ratio helps in improving fuel efficiency,

enhancing vehicle performance, and meeting stringent emission

standards.

Construction and Architecture: Aluminum honeycomb mesh is employed

in the construction and architectural sectors for applications such

as curtain walls, cladding panels, ceilings, partitions, and

decorative elements. Its lightweight nature, thermal insulation

properties, and aesthetic appeal make it a popular choice for

modern building designs.

Transportation and Railways: Aluminum honeycomb mesh is used in

various transportation systems, including trains, buses, and ships.

It is utilized for manufacturing interior panels, floors, seating

structures, and energy-absorbing components. The material's

lightweight properties contribute to fuel efficiency and provide a

comfortable and safe travel experience.

Marine and Offshore Industry: Aluminum honeycomb mesh is suitable

for marine and offshore applications due to its corrosion

resistance and lightweight properties. It is employed in the

construction of boat hulls, decks, bulkheads, and superstructures,

offering strength and durability in harsh marine environments.

Soundproofing and Acoustics: The sound-absorbing characteristics of

aluminum honeycomb mesh make it suitable for soundproofing

applications. It is used in the construction of acoustic panels,

partitions, and enclosures to reduce noise transmission and improve

sound insulation in buildings, theaters, recording studios, and

industrial facilities.

Industrial Applications: Aluminum honeycomb mesh is utilized in

various industrial sectors, including machinery, equipment, and

manufacturing processes. It is used for designing lightweight and

sturdy work surfaces, workstations, assembly stations, and tooling

fixtures.

Energy and Renewable Energy: Aluminum honeycomb mesh is employed in

the energy sector for manufacturing components such as solar

panels, wind turbine blades, and lightweight structural elements

for power generation and transmission systems. Its lightweight

properties contribute to easier installation and transportation.

These are just a few examples of the many applications of aluminum

honeycomb mesh. Its versatility, combined with its lightweight and

high-strength characteristics, make it a preferred choice in

industries where weight reduction, structural integrity, and

performance are crucial factors.

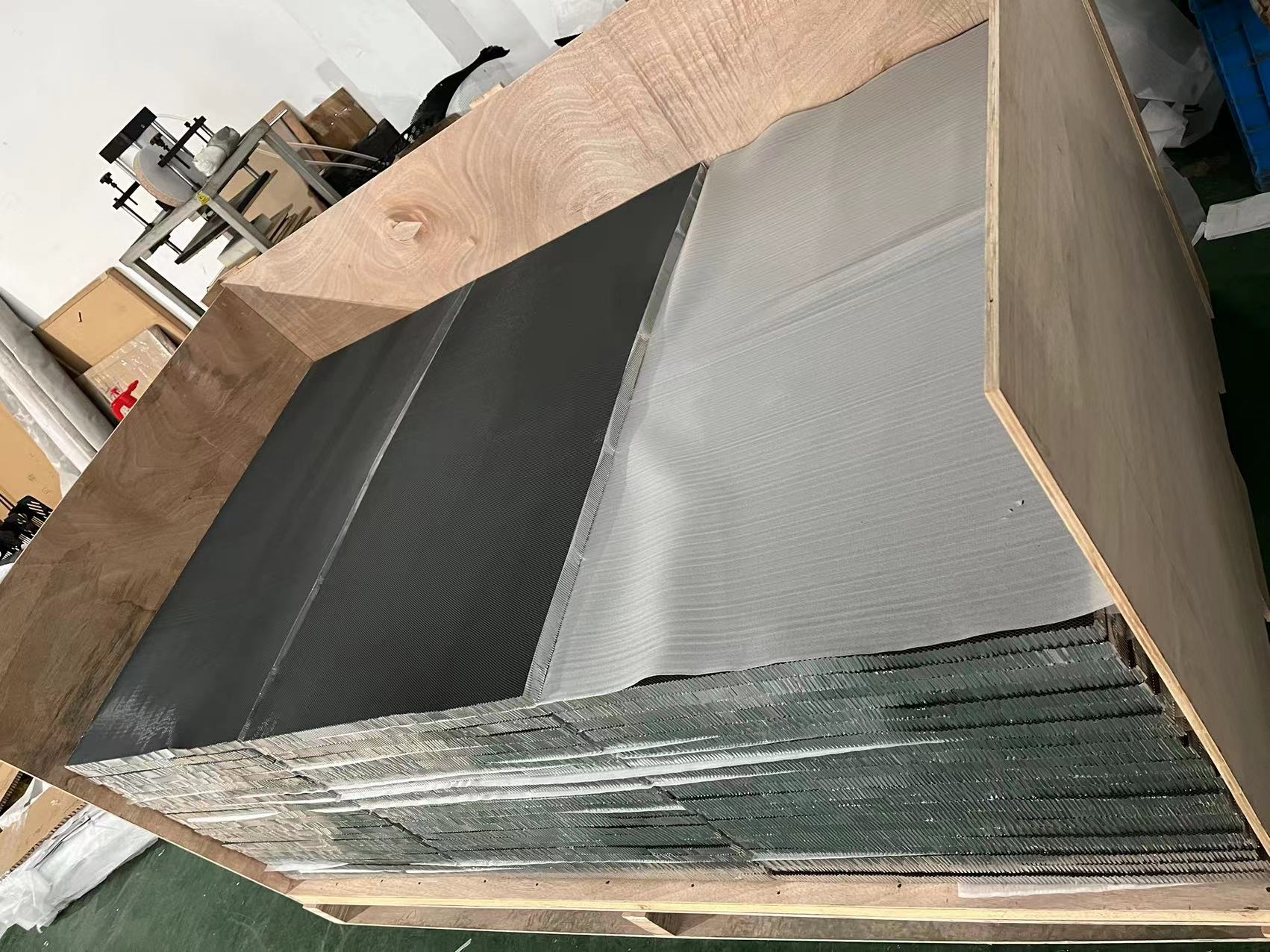

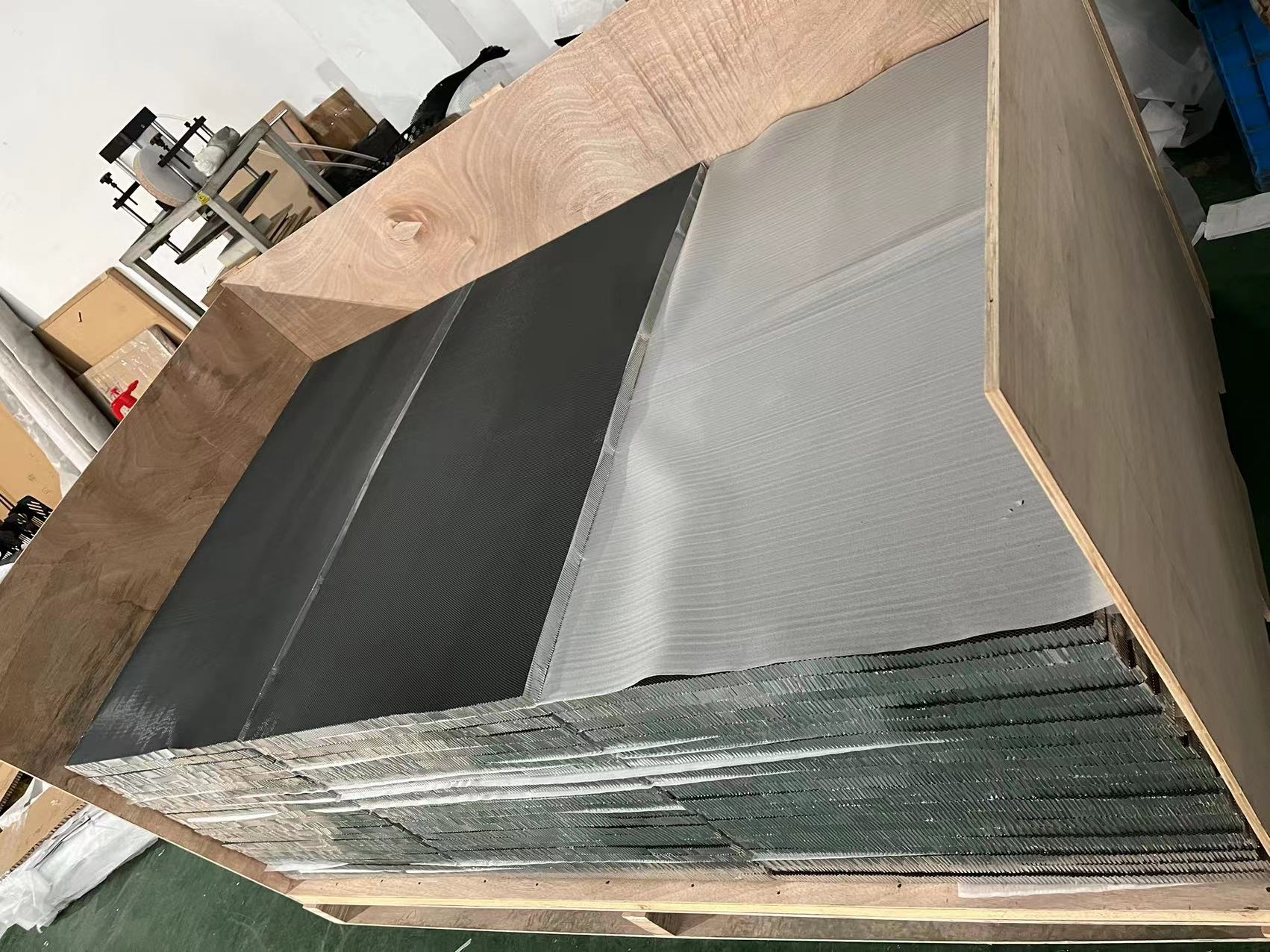

Packing and Shipping of aluminum honeycomb mesh:

We package Aluminum Honeycomb mesh with the utmost care to ensure

safe and secure shipping. We use a combination of protective

packing materials such as bubble wrap, foam, and/or corrugated

cardboard to protect the core from any damage during the transport.

We use a variety of carriers for shipping, including USPS, UPS,

Fedex, and DHL. Our shipping rates are typically based on weight

and destination.

Our goal is to get your Aluminum Honeycomb mesh order shipped as

quickly and safely as possible.

FAQ:

- Q: What is Aluminum Honeycomb Mesh?

- A: Aluminum Honeycomb Mesh is a lightweight core material made of

aluminum foil, honeycomb structure and adhesive. It has many

advantages such as good flatness, high strength, low weight,

corrosion resistance, sound insulation, etc.

- Q: Where does Aluminum Honeycomb Mesh come from?

- A: Aluminum Honeycomb Mesh is made in China.

- Q: Is Aluminum Honeycomb Mesh certified?

- A: Yes, Aluminum Honeycomb Mesh is certified with ISO 9001.

- Q: What is the minimum order quantity for Aluminum Honeycomb Mesh?

- A: The minimum order quantity for Aluminum Honeycomb Mesh is 200

sheet.

- Q: How is Aluminum Honeycomb Mesh packaged?

- A: Aluminum Honeycomb Mesh is packaged in plywood case.

- Q: How long does delivery take for Aluminum Honeycomb Mesh?

- A: Delivery time for Aluminum Honeycomb Mesh is 7-10 days.