Automatic Glue Spraying Machine Model BHM-GS-1200 (Reinforced)

Automatic Glue Spraying Machine Model BHM-GS-600 (Standard)

1. Descriptions:

Model BHM-GS-600 (standard)

Dimensions of spraying chamber: 600x2000x2000mm.

1) Rubberized roller with a stroke length of 3 meters; roller

movement can be adjusted according to production needs.

2) Transportation tape with individual dimensions. Upon request of

the customer, glue tank can be placed above the tape on a special

shelf or next to the machine.

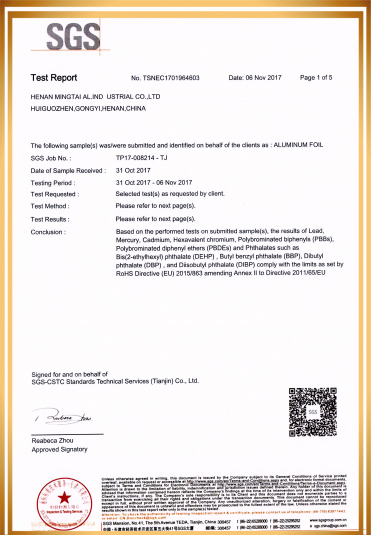

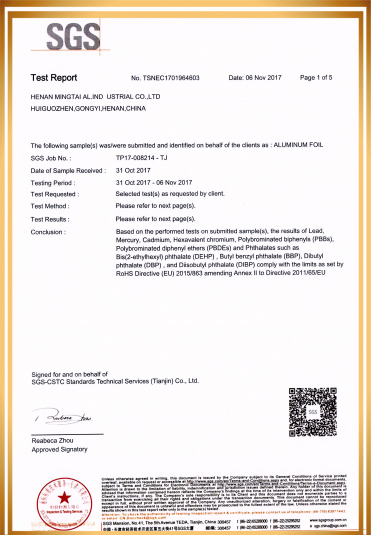

Model BHM-GS-1200 (reinforced)

Dimensions of spraying chamber: 1200x2000x2000mm. 1) Rubberized

roller with a stroke length of 3 meters; roller movement can be

adjusted according to production needs.

2) Transportation tape with individual dimensions. Reinforced

frame, which allows you to place a container with glue on the top

of the machine by placing the vinyl container on a two-layer

bracket. Glue is automatically weighed thanks to the weight sensor;

there is an automatic reminder function for glue refill.

2. Specifications:

| Automatic Glue Spraying Machine |

| Description | Unit | |

| Production rate | m/min | 1000-4500g/ min |

| Coating width | mm | 600- 1600mm |

| Positioning accuracy | mm | ±2 |

| Dosage accuracy | mm | ≤±2% |

| Air supply | bar | 6.0-8.0 |

| Power supply | / | 3 phase, 380 V, 50HZ |

| Capacity max | mm | 8.0 KW |

3. Equipment has several advantages:

Automatic Glue Spraying Machine- Advanced control process, easy operation, measurement accuracy,

uniform glue distribution, precise positioning, self-cleaning

function. Intelligent determination of length and width of the

product, precise laser positioning, adjustment of glue volume and

spray speed ratio with touch of a button. The machine is equipped with a buffer heater that continuously heats

the panel without stopping and shifting, thus ensuring continuous

production.

4. Applications:

Automatic Glue Spraying Machine is designed for rapid uniform

application of glue onto large areas during production of composite

panels for different fields: automotive industry (panels for

trailers and FRP panels for refrigerated wagons), car building,

construction materials (fire-resistant doors, thermal panels,

fireproof screens made of mineral wool), furniture production

(including kitchen and paper panels, etc.)

5. Automatic Glue Spraying Equipment of more pictures:

6. Company profile

Suzhou Beecore Honeycomb Materials Co.Ltd, originated from Besin

(Dutch) International Group which was founded in 1957. It is the

world's leading professional manufacturer of honeycomb materials.

Since it' s established, the company has been committed to the

research and development of honeycomb technology, from slant-porous aluminum honeycomb core, honeycomb core, honeycomb panel, to the finished product which was

using honeycomb panel as the solution, such as truck body, laser TV

/ projection screen etc.

7. History

1957 Besin (Dutch) International Group was established and dedicated to

research and development of BEECORE and BEEBOARD.

1958 Besin brought honeycomb technology into China, and Besin (Suzhou)

company was established.

2002 Beecore (Guangdong) factory was established and have 10 aluminum

honeycomb production lines.

2009 Suzhou Beecore Honeycomb Materials Co., Ltd was established and

mainly produce aluminum honeycomb core and paper honeycomb core and

other products.

2010 Beecore products are widely used for railway industry, Shanghai Expo, marine

furniture etc.

2014 Beecore developed micro-porous aluminum honeycomb core and slant-porous aluminum honeycomb core, as well as honeycomb filters.

2015 Beecore added honeycomb panels production lines, specialized in

super length, width, curved, and special honeycomb panels of

industry field.

2016 The self-developed aluminum honeycomb equipment has been exported

to Europe, America, Asia and already obtained the technology patent

in China.

2017- so far Suzhou Beecore Honeycomb Materials Co., Ltd is honored as the

high-technology innovation enterprise.

8. Factory picture

9. Exhibition Show

10. Company certificate